- Detail

- Parameters

- Review

KLTHG-4WA-1700A

Description | Model | Quantity | Unit value ($:USD) | Total Value ($:USD) | |

1 | CNC 4 Axis Welding Robot | Model:KLTHG-4WA-1700 | 1set | ||

AC 220 V ,50/60HZ | |||||

X axis travel:1700mm | |||||

Y axis travel: 1000mm | |||||

Z axis travel: 500mm | |||||

R axis travel: 0-400 degrees | |||||

Absolute encoder servo motor(Chinese brand) | |||||

CNC 4-Axis Linkage touch screen controller | |||||

TBI wire rod and guide rail | |||||

2 | Double station work table | Platform size 1840 * 940mm, Contains control button box | 1set | ||

3 | Welding Power Supply | YD350GL4 (CO2/MAG/MIG)(Panasonic) | 1set | ||

AC 3*380V ,50 HZ | |||||

Load rate60% | |||||

Contain: Wire feeder | |||||

4 | Fixture | Special tools for stationary products | 6 set | ||

6 | Port fees | Container port costs | 1 set | ||

FOB Total(USD): | |||||

Quotation description: | |||||

1, This offer is valid for 10 days from the date of quotation; | |||||

2, Delivery cycle:35 working days after signing; delivery mode: Port of Tianjin ,China; | |||||

3, Payment: full payment, delivery;The freight includes arrival at port; | |||||

4, Payment method: T/T ,Prepay 40%, pay 60% within 5 days before delivery ; | |||||

5, This price does not include overseas engineering installation services, such as installation services, the specific price in communication | |||||

The following is optional parts | |||||

1 | Analog module | Robot and welding power communications (0V-10V) | 1 set | ||

4 | Anti-collision welding torch | RS-350. water-cooled welding torch | 1 set | ||

Custom machine requirements

1. Workpiece data

Carbon steel products:

2. Working flow of NC welding robot

(1) First place the base product on the platform and then fix it with a special fixing fixture. This ensures repeatability of the workpiece and prevents deformation of the workpiece during the welding process.

(2) Obtain the required machining program in CNC welding control

(3) Press the start button on the workbench, and then the welding robot automatically performs all-position welding of the workpiece.

(4) Manually remove the workpiece after welding

(5) Repeat the above steps

3. Workpiece welding budget time:

(1)Welding time of station A:The total length of the weld is about 84mm, The robot is assumed to be idle for 1.5 seconds at each weld location.The initial welding speed is 600mm/min.

So the welding time of A station is =3*84/600+(1.5×3)/60≈0.45min=27s

(2)Welding time of station B:The total length of the weld is about 42 mm, The robot is assumed to be idle for 1.5 seconds at each weld location.The initial welding speed is 600mm/min.

So the welding time of B station is =3*42/600+(1.5×3)/60≈0.25min=15s

4. Workpiece precision requirement:

(1)The surface of the work shall not affect the quality of welding oil, rust, moisture;

(2)Must not affect the positioning of burrs, etc.;

(3)The clearance shall be no more than 1mm;

(4)The consistency error of the same weld group is less than 0.5m。

The workstation mainly consists of arc CNC 4 Axis welding robot, Double station table,YD-350GL4 welding power supply , carbon dioxide gas bottle, external start button box and so on.

2. Numerical control welding robot workstation layout: (picture for reference only)

Workstation configuration table

Name | Model:KLTHG-4WA-1700A | |

1 | Cnc 4 Axis welding Robot | Model: KLTHG-4WA-1700 |

Main configuration:4 Axis linkage | ||

2 | Double station table | Platform size 1840 * 940mm |

3 | Welding power supply | YD350GL4 (CO2/MAG/MIG)(Panasonic) |

4 | Fixture | KELITE Weld |

5 | External control box |

1、host equipment parameters and development instructions:

1.1 machine characteristics:

CNC four axis welding machine is a digital, similar to the 6 axis joint robot, can achieve four axis simultaneous linkage, and efficient implementation of various types of plane 2D and space 3D arc welding special CNC welding equipment. The main machine is welded by four axis vertical coordinate system. X, Y and Z are linear axes, and the R axis is the rotating shaft.

1.2 Main technical parameters:

1.2.1In the teaching mode, the welding track can be recorded automatically as long as the track is moved by hand and taken into each moving point. Greatly save programming time, simple learning

1.2.2 Control system specific motion control chip technology can achieve 4 or 5 axis linkage, with PLC can achieve complex sequence of action requirements, high speed stability.

1.2.3, The executive part adopts AC servo motor to realize high precision, high speed operation and high stability.

1.2.4, The transmission part uses the Taiwan TBI precision ball screw to improve the repetitive positioning accuracy and service life, guide the use of silver linear guide, accuracy and service life and reduce the noise of the machine, wire rod repeat positioning accuracy within 0.1mm.

1.2.5,The installation method adopts floor mounted type, greatly improving the flexibility of the machine.

1.2.6, The machine is simple to operate and has high stability. It can be operated by ordinary workers without professional welders.

1.2.7,The price of the welding manipulator is only 20% of the joint manipulator and greatly reduces the use cost, and is the real manipulator.

Effective stroke of X axis | 1700mm |

Effective stroke of Yaxis | 800mm |

Effective stroke of Z axis | 500mm (Standard not customizable) |

Effective stroke of R axis | 0-400degree |

Maximum operating speed | 700mm/S or 42m/min |

Repeatability positioning accuracy(Depending on the mechanical part) | ±0.1mm |

Programming form | Teach mode and manual mode |

X、Y、Z、R Axis motor | Absolute encoder servo motor |

Drive parts | Taiwan TBI |

Control system | 5 axis linkage, can be upgraded to expand |

Input/output | 24 inputs, 12 outputs |

Program storage | Memory 30M |

Main input power | 220V 50HZ/60HZ |

CNC system power | DC 24V |

Welding method | MAG/MIG |

Gas protection | CO2 or mixed gas |

*****Analog module*****

1. The welder analog module means that the current and voltage of the welding power supply

can be directly set by the CNC controller. Adding this kind of module can realize one or more

welding seams to obtain different voltages and currents.

2. Setting method: Only the percentage of current and voltage need to be set in the controller.

3. if there is no such module, you can only manually adjust the knob in the welding power supply

to set the current and voltage. In automatic welding, the current and voltage of each weld are almost the same.

2、Host overall arrangement

The equipment consists of welding main machine, control system, welding power supply and so on. Each system is connected by cable to form an organic whole, which is convenient for the installation and maintenance of equipment.

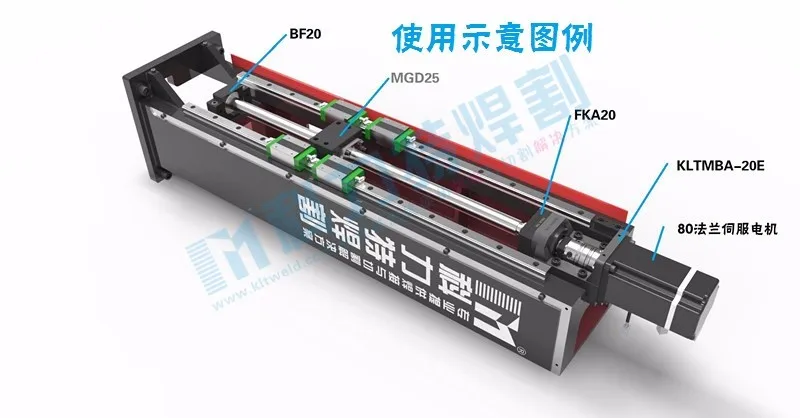

1、Bed base,2、X axis walking slipway,3、Z axis lifting slide table,4、Y axis linear module,5、R axis rotation axis,6、Wire feeder assembly, 7、Welding power 8、Wire feed plate 9、Power switch 10、Control button 11、External control signal port

3、Welding Power Supply

4、CNC Welding Controller

Power control

Name: AC servo motor

Brand: Zhishan

Original: China

High speed type, absolute value control, Ethernet interface

Movement mechanism

Name: Linear motion mechanism

Brand: TBI

Original: Taiwan

High precision imported linear guide rail, ball screw, linear slider

Machine Parts

Name: Planetary reducer

Brand: Zuolan

Original: China

High precision, 3 arc minute, high torque, low noise reducer

Mold cast aluminium parts

Name: Z axle lifting slide table

Brand: KELITE

Original: China

Cast aluminum process, structure blue, slightly high. Easy to NC milling machine processing

8 Package

After the production is finished for all theequipment, the seller should make suitable package for certain equipment partsand label the parts. Besides, the equipment package shall be intact during theloading, unloading and transportation.